Smart Wasp Intelligent Technology (Suzhou) Co., Ltd.

- +86 0512 8781 7868

- export@smartwasp.com

Smart Wasp Intelligent Technology (Suzhou) Co., Ltd.

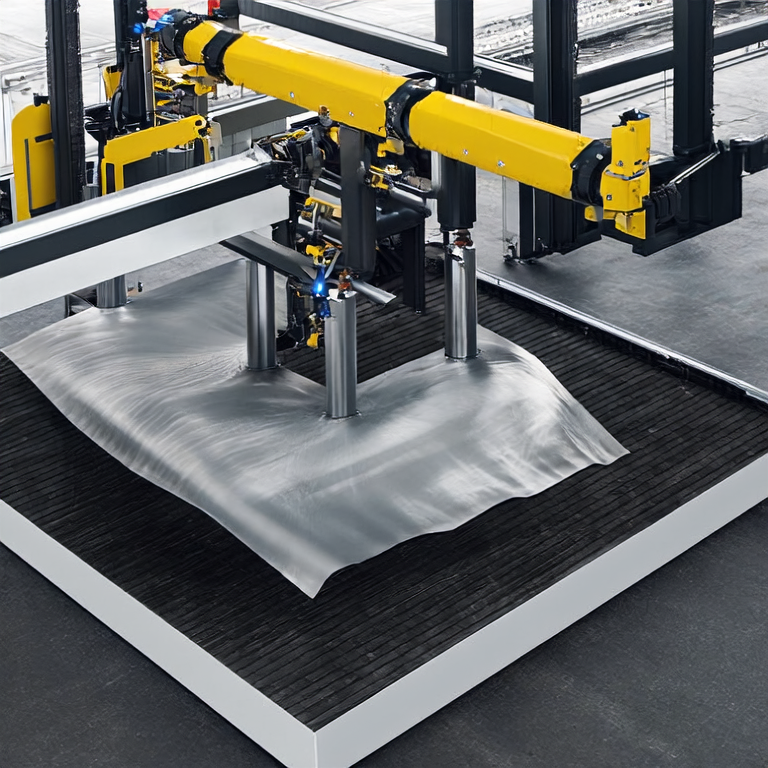

In the modern industrial landscape, the efficiency of logistics and product storage is crucial. One variable that has reshaped these processes is the Pallet Wrapping Machines for Irregular-Shaped Loads. These machines have emerged as vital tools in industries where uneven or awkwardly shaped items are transported, particularly in mining operations. The pain points of securing and stabilizing these irregular loads have often led to increased damage rates and unanticipated costs. With tailored solutions like advanced pallet wrapping technologies, companies are witnessing improvements in load stability, operational efficiencies, and overall safety standards. The increased need for optimized logistics in the mining sector calls for sophisticated equipment that can handle such challenges.

Pallet wrapping machines are designed to securely wrap products on pallets with stretch film, enhancing load stability during transportation. These machines come equipped with advanced technology that addresses specific applications—especially when dealing with products that don\'t conform to traditional shapes. The term "stretch wrapping" refers to the process of using elastic film to tightly package products. Industry experts like those at Packaging World have noted that implementing automated wrapping systems can reduce workplace injuries by up to 50% due to less manual handling.

The use of pallet wrapping machines extends across various fields, but they play a particularly critical role in:

Mining: In mining operations, where materials often come in uneven shapes and sizes, these machines ensure that products remain intact during transport.

Construction: The construction sector frequently deals with oversized and irregular loads, making robust wrapping essential for safety.

Retail Distribution: Ensuring that products are stable during transportation and storage leads to better inventory management and decreases breakage rates.

The importance of pallet wrapping machines lies in their ability to enhance load stability. Here are some quantified advantages:

Reduced Product Damage: Reports have shown that companies can lower the incidence of product damage by as much as 60% through the use of quality wrapping machines.

Time Efficiency: Automated wrapping machines can wrap pallets in as little as 12 seconds, drastically reducing downtime when compared to manual methods, which can take several minutes per pallet.

Cost Savings: By preventing damage and optimizing load efficiency, businesses can see a decrease in logistical costs by up to 20%.

For companies considering the integration of pallet wrapping machines into their logistics, it is essential to read the user guide thoroughly, ensuring full comprehension of operational protocols, maintenance, and safety standards. Engaging with a trusted brand like SMART WASP can provide insights into selecting the right machine for specific operational needs.

1. How do pallet wrapping machines adapt to irregular loads?

Pallet wrapping machines are designed with adjustable arms and varying film tension to securely wrap items that are not uniform in shape or size.

2. Can these machines be used for different industries beyond mining?

Yes, pallet wrapping machines are utilized in various sectors including construction, food and beverage, as well as retail for their efficiency in securing loads.

3. What is the average lifespan of a pallet wrapping machine?

On average, with proper maintenance, a pallet wrapping machine can last between 10 to 15 years, making it a long-term investment.

To optimize your logistical operations with pallet wrapping machines for irregular-shaped loads, consider a trial with SMART WASP. Their machinery is built to meet the specific needs of industries like mining, ensuring that your operations remain efficient, safe, and cost-effective. Exploring the capabilities of these machines will undoubtedly enhance your operational effectiveness.

For further understanding or a trial of SMART WASP’s pallet wrapping solutions, visit their website today!

Recommend Products: